Hello,

TL;DR: I'd like to understand what I'm doing wrong here, either in the program or conceptually.

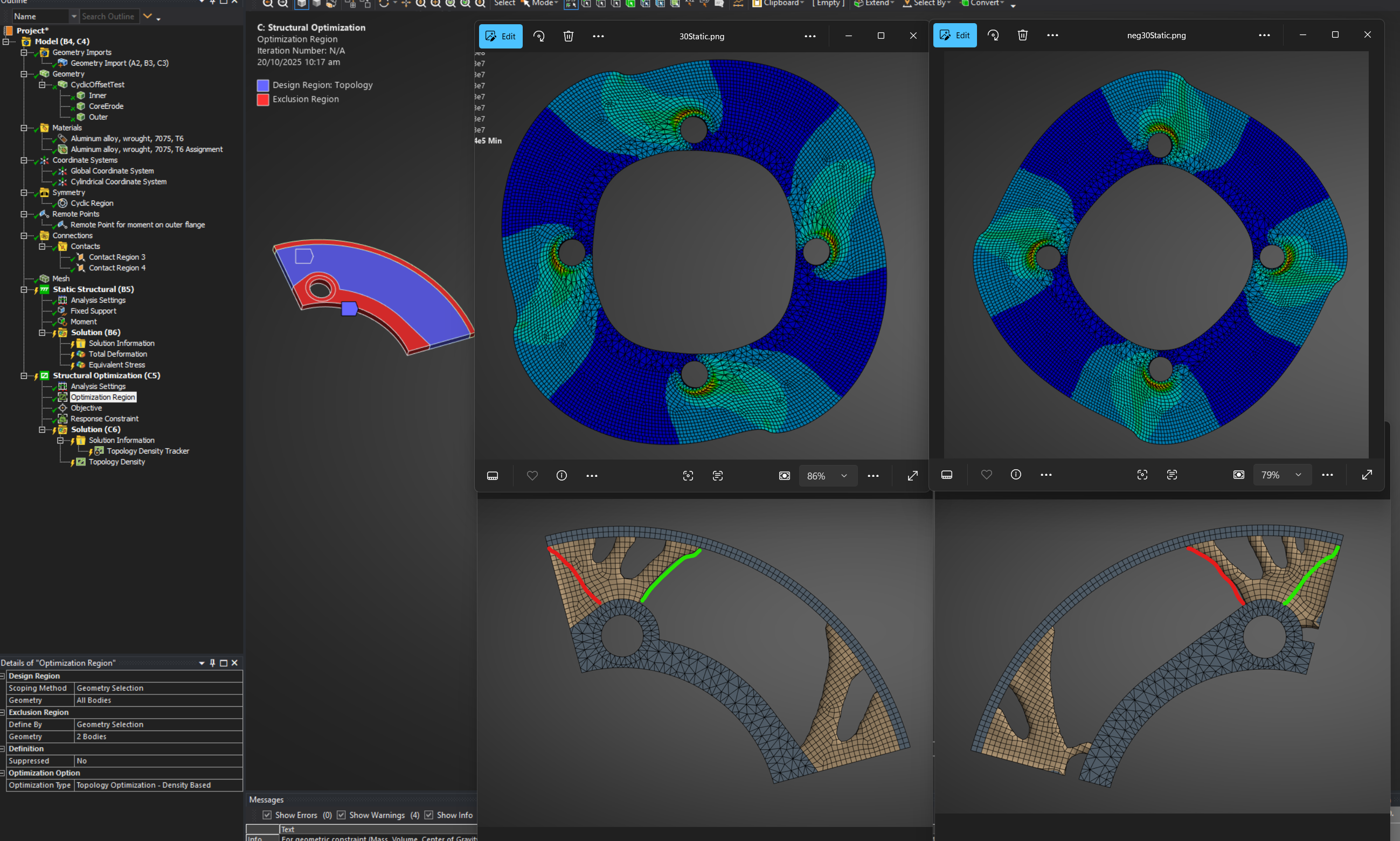

I have a part with 4-way cyclic symmetry and have applied a basic structural analysis and structural optimization to it. However, results differ according to the angle that I cut the geometry.

Shouldn't results be the same, or at least very similar (depending on meshing)?

More details:

I have a disc with 4 fixed supports around the bolt holes, and an in-plane torque applied to it via remote point around the outer flange.

The disc has three bonded parts of the same material: an inner section, an erodable mid-section to be optimized, and an outer flange.

I enabled Beta functions in the Static Solution that allow me to see the 4 sections in the top two images (it simply repeats the part 4 times). You can see that the results for Von-Mises Stress are not the same.

Below that you can see how this affects Topology Optimization results, where you get two very different solutions for the same inputs. The only thing being different is the angle or 'phase' that the original part was cut.

Question: Why does the cut angle affect the results? I assumed cyclic symmetry should make them identical?

Thanks!